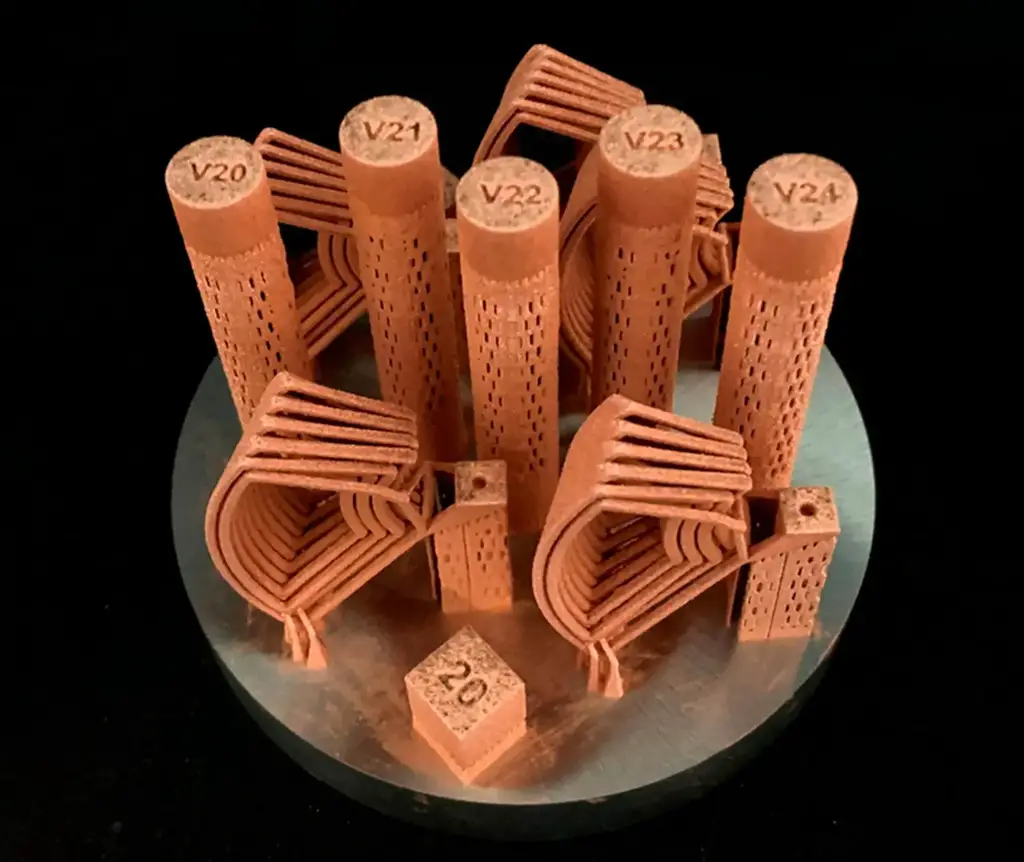

These are test versions of electromagnetic coils – versatile tools for space missions – which have been 3D printed in pure copper to produce the required magnetic field shapes. Credit: ZARM Technik AG

The <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]”>European Space Agency’s General Support Technology Programme celebrates three decades of technology advancements, notably in developing 3D-printed electromagnetic coils for space missions, reflecting the program’s critical role in supporting innovative space technologies.

Recent advancements in space technology have seen the creation of electromagnetic coils through 3D printing in pure copper. These innovations allow for the precise production of magnetic field shapes essential for space missions. This development is a result of one of the numerous research contracts supported by the European Space Agency’s (ESA) General Support Technology Programme (GSTP).

A selection of copper coils created by additive manufacturing techniques. These benchmark geometries were produced by L-PBF with green laser source. The activity successfully demonstrated how the electrical conductivity of pure copper can now be combined with the design freedom of additive manufacturing – both are important factors in the performance of electromagnetic coils – and enable the production of coils with complex shapes to generate dedicated magnetic field shapes. Credit: ESA

The Role of GSTP in Technology Development

The GSTP has been instrumental in working with European industry and academia over the past three decades, fostering the development of over 2,000 research contracts. These efforts have been crucial in refining technologies for both spaceflight and commercial use.

Electromagnetic coils, a product of these research endeavors, play a critical role in electric motors, magnetic bearings, and magnetorquers used for satellite attitude control. A project led by Zarm Technik in Germany, under the GSTP, has successfully developed an end-to-end process for producing these coils using laser powder bed fusion 3D printing technology.

[embedded content]

Inaugurated on May 13, 1993, the GSTP was originally an integral part of ESA’s long-term plan to make sure the Agency kept ahead of technologies it might need. GSTP aims to work with industry, academia, and Participating States to predict what those technologies might be or to see if current innovative technologies used on Earth can be adapted for use in Space. In the programme’s lifetime over 2000 contracts have been awarded to do just that. Credit: ESA – European Space Agency

Celebrating 30 Years of GSTP

As the GSTP celebrates its 30th anniversary, its history dates back to 1993 when it became a vital component of ESA’s strategy to stay at the forefront of necessary space technologies. The program has since become a fundamental element of ESA’s technology initiatives. Notably, the GSTP operates as an optional program within ESA, yet its success is so pronounced that all ESA Member States have opted to participate. The achievements and milestones of the past 30 years of GSTP can be explored through a special video produced by ESA (see above), as well as in the latest GSTP Annual Report.